Products

3-axis CNC machining center OW-T660

Category: Machining Center Series

Key words:3-axis CNC machining center OW-T660

Product Description

Product Parameters

Product Video

3-axis CNC machining center

OW-T660

Equipment features

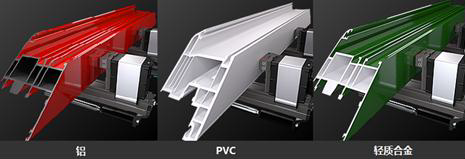

It is suitable for milling, drilling and chamfering of aluminum alloy profiles. Using Siemens 828D numerical control system, supporting the original servo motor, wire, electrical components, assembly of Italy high-speed electronic shaft, 6 tool magazine. The equipment is high-speed and efficient, the processing range is large, and the performance is stable, which meets the processing needs of various aluminum profiles.

To meet the processing needs of the above profiles

Main technical parameters:

Voltage: 380v 50HZ three-phase four-wire

Working pressure: 0.6 ~ 0.8Mpa

Total power: 12KW

Spindle (OLI Italy)

Power/speed: 8/24000KW/rpm

Feed speed

X axis: 70 m/min

Y axis: 40 m/min

Z axis: 40 m/min

machining accuracy

Positioning: ± 0.05mm

Repeat positioning: X axis ± 0.02 Y axis ± 0.015 Z axis ± 0.01

Perpendicularity of drilling and milling: 0.1/100mm

Cylindricity: 0.1mm

Surface roughness of drilling and milling surface: Ra1.6um

Processing size

X transverse stroke: 6600mm

Y longitudinal stroke: 600mm

Z depth range: 350mm

Tool magazine

Number of cutters: 6 cutters

Tool change time: 8s

Tool magazine motor: 750w

Drilling and milling cutter chuck: 16mm

Servo Motor (Siemens)

X:1.5KW

Y:0.85KW

With: 0.85KW

Control System

Simon 828D imported from Germany

Calculated number: 80 floating point number

Network disk function: support FTP protocol

Pre-reading function machine tool speed up by 50%

Absolute encoder: 24 bit (boot does not return to the origin)

Machine dimensions: 8600 × 2000 × 2300

Control box dimensions: 600x1400x1800

Weight: 3500kg

Tab ④

HTML language content can be parsed after rich text content is bound to data

The information is a test element. When using, you can delete the element and place the element you want to put.

Recommended Products